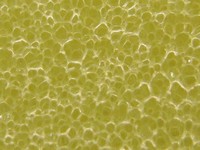

Flexible Polyurethane FoamFlexible polyurethane foam (FPF) was introduced in the 1950s, and because of it’s lower cost, quickly replaced latex foam as the preferred cushion material in the furniture industry. It now accounts for 40% of the polyurethane market in North America, and is also used in many other applications such as automotive, bedding, carpet padding, and packaging.FPF is available in many varieties. Typical densities range from 1 to 3 lb/cu ft. Common colors are white, yellow, peach, pink, blue, gray, and charcoal, however it can be made in other colors as well. Common IFD ratings are from 30 to 80, but they can be as high as 150. | | Closeup picture showing the open cell structure of flexible polyurethane foam |

FPF is also referred to as being either conventional or HR (high resiliency). HR foams are formulated in a way that produces a varied cell structure that improves support, comfort, and durability. They are usually a minimum of 2 lb/cu ft in density. They also cost more than comparable conventional foams, and are better suited for seating applications. Conventional foams are better suited for light use, or short term applications such as packaging.It’s wide spread use makes FPF a relatively economical padding material, although prices have been somewhat volatile in recent years due in part to interruptions in the supply of chemicals that are used as the main raw materials. It is extremely durable, and it is readily available in a wide variety of grades and specifications from many different suppliers.

Continue >>

| | Pages

[ << ]

[ 1 ]

[ 2 ]

[ 3 ]

[ 4 ]

[ 5 ]

[ 6 ]

[ >> ] |

|